Food & Beverage

IES Lean Systems Ltd. has a long association with the Food & Beverage Industry, having completed numerous projects from simple remediation to complex MES systems. Product traceability is an increasingly important factor in food production. IES Lean Systems Ltd. has considerable experience in EBR (Electronic Batch Records), Digital Signatures, RFID (Radio Frequency Identification and other pertinent technology.

IES Lean Systems Ltd. have experience in projects in Food & Beverage in the following areas:

MES Application

Pasteurisation

Line Monitoring

Energy Monitoring

OEE & Waste

Pasteurisation

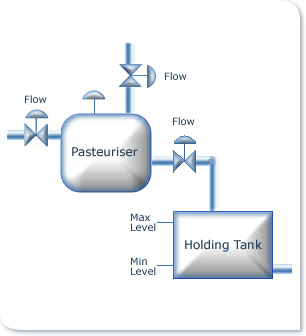

Pasteurisation is an essential component in many food processes. The traditional approach is wasteful in energy use, inefficient and unreliable. Traditional pasteurisation processes for pasteurising beer is based on maintaining an elevated temperature for a predetermined time. Whilst suitable in an era when beer was brewed in standardised batches it has proven unsuitable for adaptation for the modern brewing process. The difficulty arises due to the requirement to accommodate widely varying flow rates through the process which invalidates the energy calculations made in conventional pasteurisation. Such pasteurisation systems are often run at slightly over-temperature set points to ensure complete kill levels of bacteria, this can have an adverse affect on taste and certainly increases energy consumption. If lower temperatures are used the process can be rendered ineffective with consequent health risks and the requirement to reprocess product. As a result variable flow rates cause the product quality to fluctuate. The ies solution adds far more flexibility by resolving the kill rate calculations within the control units arithmetic unit. It calculates the required energy input to the process based on “pasteurisation units” derived from flow rate, temperature and product resident time. The resulting system installed by ies controls both flow and temperature , maintaining product level at the holding tank within the min and max levels that can be handled by the filling process. This solution can handle significant variations in flow and offers flexibility when different products are being processed on the same system.

OEE& Waste Management

In today’s ultra competitive world there is an ever increasing need to increase production efficiency and cut waste. IES Lean Systems Ltd. has many years experience in OEE (Overall Equipment Efficiency) and Waste Reduction. The system illustrated was installed at a major Pet Food production unit but is equally applicable to many other manufacturing applications both inside and outside the Food industry. The system graphically displays the current status of all machines including the duration, cause and frequency of all stoppages. Other screens display the calculated efficiencies. In addition to unit and machine level information the system provides overall Production Data and facilitates comparisons between individual production lines, shifts and times. The displays shown here are bespoke to the application and can be tailored to display the information in different forms to suit the particular client and application. Reports can be produced on demand or by shift and again ies systems may be easily customised to suit individual requirements.